This introduction to liners will help you understand their purpose and common types available for sealing your packaging to perfection.

Which Liner Could Be Right for My Application?

The liner type will depend on what you are adhering the cap to (the resin or material of your container). We recommend you have an idea of what type of liner would be best for your product and operations, as there are many options. We have outlined the two categories of liners, non-induction and induction, to give you an idea of what to expect on involvement and investment depending on which route you take. We have also provided some common liner types that fall under each category, and their typical industry and product applications those liners could be a fit for.

Types of Liners

NON-INDUCTION LINERS

Non-induction liners create a barrier that helps prevent leakage and extends the shelf life of the product, but they are not tamper evident. You do not need equipment to apply these liners.

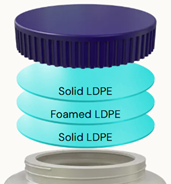

Foam Liners

Standard foam liners consist of a foam middle with a top and bottom layer of PE. The F217 is a popular type of foam PE liner. These liners can be modified to include different polymers, films and foil. Lower foam densities, like LDPE, allow for less material usage and lower cost. HDPE can provide additional stiffness and chemical resistance. A Polyolefin and PP makeup can handle heat resistance. For a good oxygen and moisture barrier, EVOH-PE and coextruded film is an option.

- Benefits: Chemical resistance, low moisture transmission rate, taste and odor resistance, economical, stays in cap for reseal

- Common Uses: General purpose, water-based products, cosmetics, beverage, food, chemicals, pharmaceuticals

- Warnings: Not tamper evident, no hermetic seal

- Container Compatibility: Glass, metal, plastic

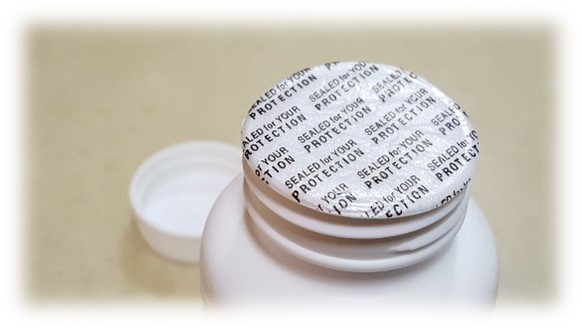

Pressure Sensitive Liners

The pressure sensitive liner consists of polystyrene foam and an adhesive side that sticks to the container rim, even after the cap is removed. A popular type of pressure sensitive liner is PS22. It provides an initial seal only for one-time use as it does not reseal. Due to market constraints, the polystyrene foam market has been shrinking. This has resulted in decreased availability of pressure sensitive liners.

- Benefits: No equipment needed to apply, no pulp dust, can come printed with “sealed for your protection”

- Common Uses: dry food products, powders, tablets, cosmetics, pharmaceuticals, nutraceuticals, personal care

- Warnings: Not tamper evident, not recommended for most liquids, not for direct sunlight

- Container Compatibility: Glass, metal, plastic

Polycone Liner

The polycone liner is not technically a liner. This “liner” is an insert that stays inside the container’s closure, sealing the lip of the container. It is also referred to as a polyethylene cone, taperseal or polyseal liner.

- Benefits: Leakproof, stays in cap for reseal

- Common Uses: Nutraceuticals, essential oils, pharmaceuticals, chemicals

- Warnings: Not tamper evident

- Container Compatibility: Glass, plastic

Plastisol Liners

Plastisol liners are not technically a liner either. This lining comes pre-applied on the inside of metal lids and lug caps that are heated to create an airtight, hermetic seal. The “pop” opening sound of plastisol lids serves as tamper evidence.

- Benefits: Hermetic seal, tamper-evident, hot-fill ready

- Common Uses: Food & beverage

- Warnings: Not suitable for high-temperature packaging

- Container Compatibility: Glass

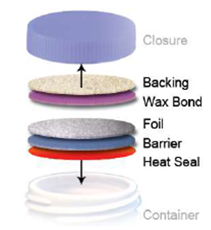

INDUCTION HEAT SEAL LINERS

Heat induction seal (HIS) liners adhere to the container with an airtight seal, preserving freshness and preventing tampering. They are sealed using equipment with an electromagnetic field that heats up the foil layer which melts the polymer layer and bonds to the container. There are many liner types and features so that you can best seal your product. The liner’s polymer layer (heat seal layer) should be compatible with the plastic or glass container.

- Benefits: Provides a hermetic seal, equipment automates the sealing process, can provide tamper evidence and reseal if constructed for that purpose

- Common Uses: Pharmaceuticals, food & beverage, chemicals, nutraceuticals, personal care and cosmetics

- Warnings: Only specific liners will work with oils and aggressive chemicals

- Container Compatibility: Glass (with universal liners), plastic

Two-Piece Liners

Two-piece liners include a wax layer between the foil layer and the pulp or foam board backing. The foil bonds to the container during heat induction and the wax melts, absorbing into the backing and remaining inside the cap. The backing then allows for reseal. Two-piece liners can include Clean Peel, Lift and Peel, Weld Seal, and tab features. Foam-backed liners are typically more expensive. Two-piece liners are often pulp-based, which is less expensive.

One-Piece Liners

One-piece liners provide a friction fit with a foam-backed or paper-backed foil laminate. One-piece are often used for wide-mouth and dispensing closures, and for food and beverage products. One-piece liners can include Clean Peel, Lift and Peel, Weld Seal, and tab features.

Vented Liners

Some products need ventilation to avoid bloating or paneling. Vented liners allow for a safe passage of air without product leakage. Vented liners could consist of a one-piece HIS for dry products, venting through a paper layer. For liquid products, the liner could consist of a membrane (with pores) and backer, or vent holes incorporated into the liner and closure. Vented liners are often used on oils, household and industrial chemicals, and fragrances.

TIPS ON CHOOSING THE RIGHT LINER

- It’s paramount to know if FDA requirements apply to your food & beverage, pharmaceutical, personal care, or chemical product packaging, as this impacts your closure and liner selection.

- Standard foam liners and standard pulp liners do not create a tight container seal and are not FDA tamper evident.

- More complex structures with more foam drive higher costs. Liners with more pulp tend to be lower cost. Find the right liner for your specific application without paying for unneeded and extra elements.

- Clean Peel liners are great for food and beverage, as they peel away cleanly from the container rim, leaving no-to-low trace of remnants.

- If you are looking for tamper evidence, a Welded Seal can be punched through by the consumer to access the product. Lift Tabs or Pull Tabs can help improve the user experience. Weld bonds are great for pharmaceutical and nutraceutical products. The FDA requires visual indication that the liner was at one time sealed, and the remaining residue on the container’s rim is proof of the seal.

- Keep in mind that the overhang of a one-piece friction fit liner can create interference with a child-resistant closure’s opening process.

- Poly Vinyl or “pulp and poly” liners are good for cold fill applications.

- If your product contents are aggressive consider adding a protective barrier layer between the foil and the heat seal layer on your induction liner setup.

The type of liner and seal process you choose should be based around your product contents, chosen container material, desired sealing operation, and consumer experience. Please contact us with questions if you need further assistance.