We know from our last post that applying vented liners is a cost-effective, eco-friendly solution to reduce the possibility that packages will be damaged by bloating or paneling. What exactly are vented liners and how do they work to keep your products safely sealed while still allowing them to breathe?

What Are Vented Liners?

Simply put, vented liners are one of the packaging industry’s solutions to reducing common packaging failures. Vented liners provide the right amount of airflow and pressure release for products so they can breathe and adapt to the environments and conditions they experience during the supply chain process.

Just as a screen protects your house from bugs flying in when you open a window for some fresh air, vented liners are manufactured and specified with precisely the right size holes and materials to ensure your particular product can breathe while keeping contaminants out.

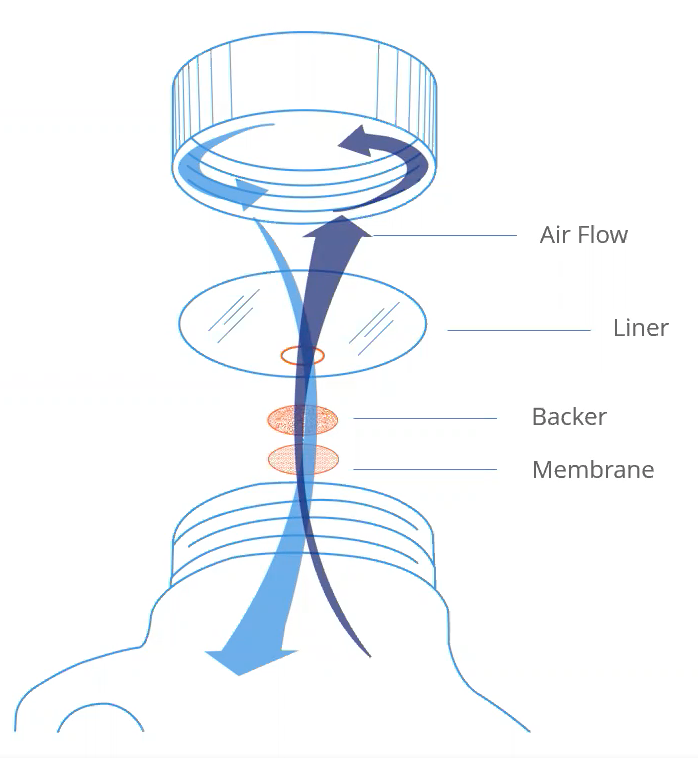

Vented liners are comprised of a series of parts that together help secure products and solve packaging problems as the products are en route to consumers. They’re made up of the liner, a membrane, a backer, and an optional cap piercing, depending on the needs of your product.

How Vented Liners Work

Now that we know what vented liners are, let’s detail how each component works. While there are thousands of possible combinations for vented liner options, all vented liners will have three main parts: the membrane, the backer, and the liner.

The membrane, which allows the proper amount of airflow and pressure through your product package, is a semi-permeable material that’s manufactured to let your package breathe and increase its life expectancy. It can be manufactured to be hydrophobic (water repellent) or oleophobic (oil repellent).

All membranes are initially manufactured to be hydrophobic, which can be great for bleach and water-based solutions or solutions with a similar surface tension to water. Oleophobic membranes are meant for more aggressive products and chemicals and those with a lower surface tension.

M-Industries Proprietary Oleophobic Vented Liners

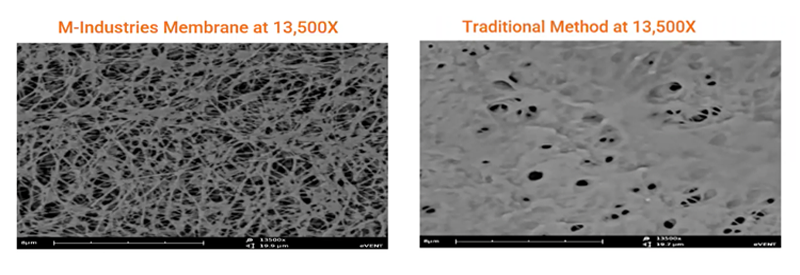

The traditional way of making oleophobic vented liners involves soaking the liners in a chemical bath. This process smothers the surface of the membrane, which reduces the level of available airflow for a product.

The coating can also be dissolved by the package contents over time. This can result in what every company wants to avoid: bloating, paneling or leaking. This method is not approved by the Food and Drug Administration for food-grade applications.

Using their proprietary method, MJS Packaging’s manufacturing partner, M-Industries, has found a way to avoid those issues and provide customers with a better product. M-Industries’ oleophobic membranes undergo a unique plasma process that coats every individual fibril of the membrane. This provides superior protection by increasing airflow, providing higher oleophobic grades and WEP ratings, and is the only membrane in the industry that is FDA approved.

Finding the Right Membrane Size

Once you’ve decided whether your membrane will be hydro- or oleophobic, you’ll have to pick the membrane size. This decision will determine how big the holes in the membrane are. Membranes are measured by pore size in microns (one micron is equivalent to 0.001 millimeters). Vented liners are not a one-size-fits-all product, and a company’s choice of membrane is no different. M-Industries offers more pore size options than any other vent manufacturer:

- 1-micron membrane: This pore size is best used for simple formulas, such as bleach, peroxide, and surfactants.

- 0.45-micron membrane: This membrane is most frequently used for household cleaners that don’t include any essential oils.

- 0.2-micron membrane: This pore size is used for most low surface tension products, like those with essential oils and agrochemical products.

- 0.05-micron membrane: This membrane is used for products with the lowest surface tension, like alcohol, mineral spirits, acids, and acetone.

Applying Vented Liners Can Strengthen Your Brand & Our Environment

We know now what vented liners are, how they work, and why they solve packaging failures like bloating and paneling. If you’re still on the fence about the benefits of applying vented liners to your products, let us leave you with this.

Vented liners are an easy and affordable way to strengthen your brand over time. A company’s brand can grow stronger by applying vented liners as they can dramatically reduce the instances of packaging failure and associated returns.

According to experts from MJS Packaging and M-Industries, as discussed in our latest webinar, 58% of customers would not place a repeat order if their package was delivered damaged; 38% of customers also wouldn’t order from the company again, and 41% of consumers say that package failures negatively impact a company’s brand.

Beyond helping you avoid a tarnished brand, applying vented liners to products can also help reduce a company’s carbon footprint. Traditionally, manufacturers have added gram weight to a bottle to eliminate bloating and paneling. The use of a vented liner achieves that goal while allowing for thinner walls of the container, therefore lightweighting the product.

A lighter weight product also reduces the amount of weight that’s being transported across the distribution process, leading to less fuel being used and emissions being burned. Products that are protected with vented liners are also less likely to be returned, resulting in less repackaging and reshipping.

How MJS Packaging Can Help

With all this information on the table, MJS Packaging’s experienced sales team wants to help assist you in making the best decisions for your product. Provide us with some information about your product’s packaging and the types of failures you’ve incurred, and we’ll help you find the right solution for your product.

Contact MJS Packaging today or talk with one of our knowledgeable packaging solutions specialists by calling (800) 915-2262.