Each year, cold and flu season challenges consumers to find effective relief from respiratory symptoms. It presents an equal challenge for manufacturers and packagers, ensuring medicines are safely and compliantly packaged for every format, from liquid syrups to nasal sprays. At MJS Packaging, our team brings decades of experience in pharmaceutical and over-the-counter (OTC) medicine packaging to help brands prepare for seasonal demand with confidence.

Our Senior Vice President Ken Goldberg and Account Executive Owen Schmidt have long supported customers across the healthcare and pharmaceutical industries, offering strategic guidance on selecting, sourcing and developing packaging designed for performance and compliance.

Pharmaceutical Industry: A Cold and Flu Overview

According to Grand View Research, the global pharmaceutical market earned approximately $1.65 trillion in 2024 and is expected to reach $2.35 trillion by 2030. Statista reports that this continued growth is driven by drug innovation and the increasing demand for affordable medication options. Within this market, OTC drugs, including cold and flu remedies, are experiencing a surge, with the OTC drug market projected to grow at a 7.92% compound annual growth rate through 2030.

According to the Centers for Disease Control and Prevention (CDC), flu season typically spikes between December and February, though activity can begin as early as fall. Flu (influenza) viruses differ from the many viruses that cause the common cold, but both contribute to the high seasonal demand for symptom relief products across pharmacies, clinics and retail shelves.

To meet this demand, MJS Packaging provides packaging solutions that ensure compliance, safety and ease of use for every dosage format, from pills and capsules to liquid medicine and nasal sprays.

Medicine Formats for Cold and Flu Relief

Cold and flu medications come in various formats to suit patient needs. One type may be more effective or easier to administer depending on age or condition. Standard formats include pills, capsules, liquid solutions, nasal sprays, inhaler sticks and topical rubs or balms. Each requires a packaging strategy to ensure safety, compliance and usability.

Types of Cold and Flu Packaging

Pills and Capsules

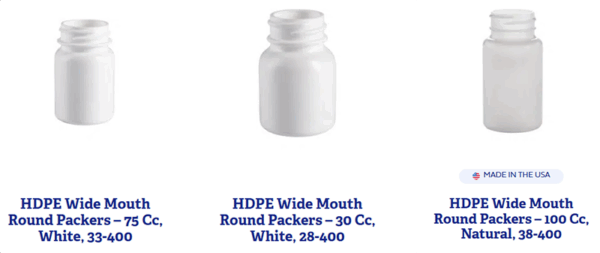

Among the most common formats, pills and capsules continue to dominate pharmacy shelves. MJS Packaging supplies both glass packers and plastic packers that meet the required volume, wall thickness and safety standards for cold and flu medications.

Our team helps determine the ideal bottle size based on capsule count and size, while factoring in space for cotton or desiccant if needed. We also offer lightweight packers that reduce material use without compromising quality to support sustainability goals.

Regarding caps, we carry a wide selection of child-resistant closures (CRCs) with push-down-and-turn mechanisms and easy-to-understand pictorial or text directions, an essential safety measure for OTC pharmaceuticals.

MJS Packaging provides both stock and custom solutions, ensuring brands can achieve the right balance between rapid fulfillment and tailored design.

Liquid Medicine

From cough syrups to multi-symptom relief formulas, liquid medicine packaging remains one of the most diverse and specialized segments of cold and flu packaging. It’s also a preferred option for children and elderly patients who may have difficulty swallowing pills.

Liquid cold and flu medications are often sold with a separate dosage cup that is usually shrinkwrapped to the bottle, on top of a CRC. However, “now the tendency is to go with a molded closure that can serve as both primary closure and the dosage cup, and we have that option,” explains Ken Goldberg. “That narrows down the field to only bottles with that specialty-type neck. That typically saves cost because you’re eliminating a component. You have to have the right equipment and an absolute match.”

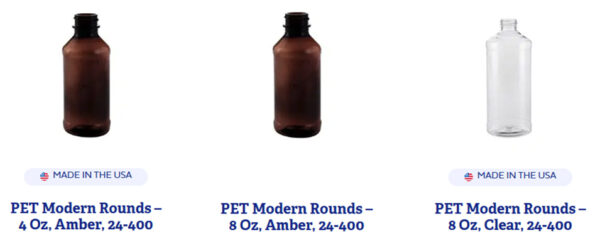

In general, standard bottle options include modern round and Boston round containers with narrow neck finishes. From cough syrup bottles to children’s liquid medicine packaging, we’ve got you covered.

For pediatric applications, oral syringes with graduated markings can be paired with child-safe bottles to ensure dosing accuracy and safety.

“It’s the dosage delivery system that will determine if we can find an off-the-shelf solution. It gets very costly if you’re looking to develop the dosage solution.” We always help customers identify the right balance between cost, performance and speed to market.

Whether you need stock bottles for fast delivery or a custom-molded solution, MJS Packaging helps you optimize your packaging for compliance and efficiency.

Nasal Sprays

Nasal spray packaging must deliver precise dosing while maintaining product integrity. “Most often, nasal spray packaging consists of a 10ml to 30ml bottle with an accompanying sprayer that delivers a specified dose in one or two sprays,” says Ken.

MJS Packaging supports these applications with plastic Boston rounds and nasal packaging that includes specialized nasal pumps or sprayers with overcaps and child-resistant options.

Testing is a critical step in the process. It’s the product manufacturer’s responsibility to get the dosing right and determine how that product interacts with the spray engine. There may be a stock pump option that could be a fit for your output. Ken shares, “that’s why it’s important to talk to us, because we shorten up the development lead time. Nasal spray packaging development could be between 16 – 24 weeks if there is a lot of back and forth, but that can shorten down to 6 – 8 weeks.”

“We know what questions to ask,” explains Ken. “If we give a packaging manufacturer the right guidelines, we can hit it the first time out of the gate.” If you need a custom spray solution or nasal pump, we can develop one that has optimal delivery based on the product formulations.

Nasal Inhalers and Vapor Rubs

Nasal inhaler sticks offer a convenient format for consumers seeking quick, on-the-go relief. MJS Packaging can support these with custom molds for nasal stick packaging, helping brands achieve distinctive designs for their preferred look and user experience.

For topical applications such as mentholated ointments and vapor rubs, we provide wide-mouth jars, roll-on sticks and tubes suitable for semi-solid formulations. These solutions ensure easy application and safe storage while maintaining brand aesthetics and functionality.

Expert Tips for Cold and Flu Packaging

1: Plan Ahead for Supply Chain Demand

Owen Schmidt states, “The most popular item in demand is an 8 oz PET plastic bottle with a 24mm child-resistant cap. There’s always a run on the components, so inventory ramp-up is critical.” He recommends establishing forecasting and supply agreements with blanket order to ensure line time and on-time delivery.

2: Work with FDA-Compliant Manufacturers

Ken emphasizes the importance of compliance: “It’s always good to know that your packaging manufacturers follow Good Manufacturing Practices (GMP) and that they have FDA-approved materials, including resins and colors. It’s best to work with manufacturing partners that follow FDA guidelines and have a Drug Master File (DMF) reference.”

MJS Packaging partners with experienced pharmaceutical packaging manufacturers that provide drug master files.

3: Consider Custom Packaging Innovation

Looking to launch a new packaging format? MJS Packaging can help bring your idea to market efficiently. Whether it’s a new applicator tip or a unique nasal stick design, we can start custom mold tooling projects at lower costs. Working with a distributor offers flexibility, access to multiple suppliers and faster turnaround for prototypes and production runs. Explore our custom packaging solutions to learn more.

Partner with Experts in Pharmaceutical and OTC Packaging

From liquid cough medicines to menthol rubs, there’s a wide range of cold and flu packaging types available to fit each product format. The pharmaceutical and OTC markets are evolving rapidly. Working with an experienced packaging partner ensures that your products stay compliant, shelf-ready and cost-effective.

As Ken emphasizes, “We’re constantly in touch with our key manufacturing partners so we can stay aware of leading-edge technologies for dosage delivery across different OTC medications.”

When you’re ready to develop or refine your cold and flu packaging, our team is here to help. Start a project with MJS Packaging to gain access to expert guidance, stock and custom solutions and a partner who understands the science and strategy behind effective healthcare packaging.

Leave a Reply